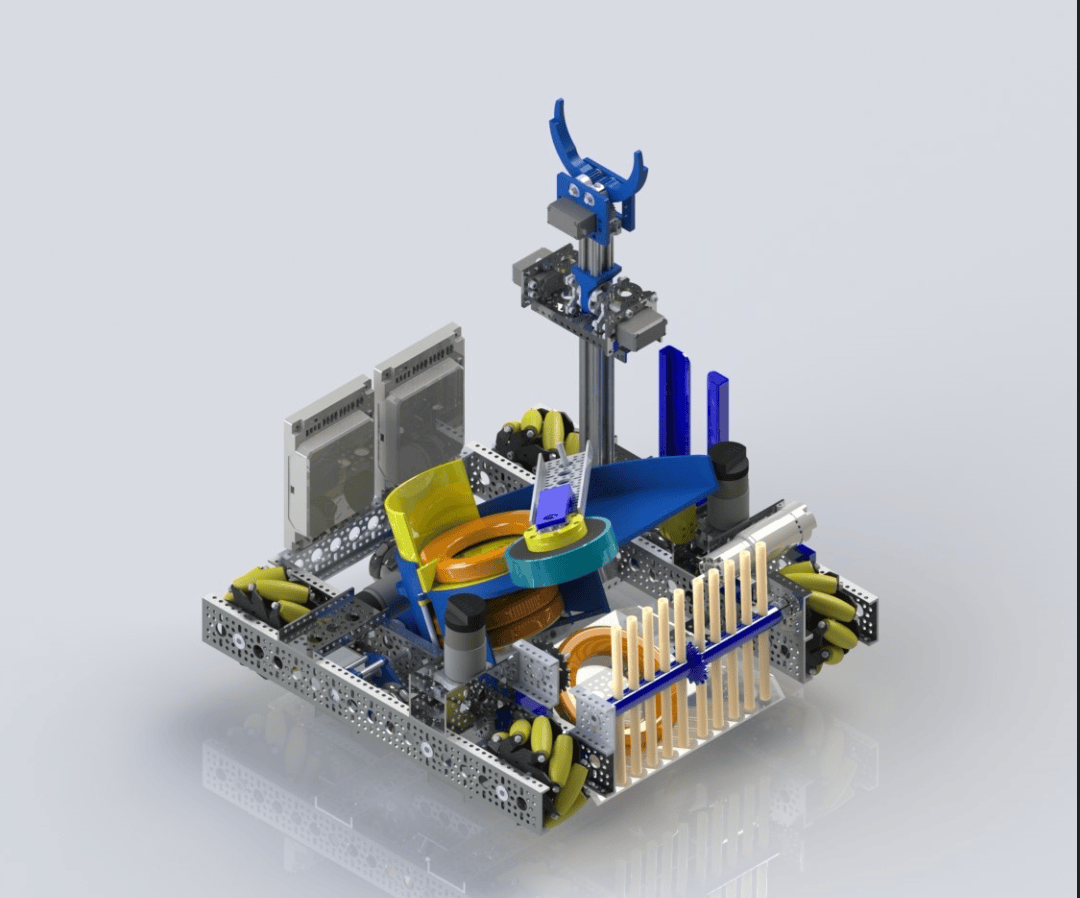

Kryptos: FTC Robot

September 2020 - February 2021

As Team Cypher's co-captain and build lead during the FTC Robotics 2020-21 hybrid competition season, I led the team in designing and building Kryptos, an advanced robot capable of performing various complex tasks during the competition.

Project Overview

The "Kryptos" project was part of the FIRST Tech Challenge (FTC) Robotics competition for the 2020-21 hybrid season. As the co-captain and build lead of Team Cypher, I was responsible for overseeing the design and construction of our robot, Kryptos. The robot was developed to perform a range of tasks, from navigating a complex course to interacting with game elements, all within the constraints of a pandemic-adapted competition format.

Design and Build Process

Our design process began with brainstorming sessions and initial concept sketches, followed by CAD modeling using SolidWorks. The team adopted a modular design strategy to facilitate easy adjustments and repairs, which was crucial for maintaining performance throughout the competition. The robot's design evolved through multiple iterations, each focused on optimizing specific subsystems like the drive train, intake mechanism, and shooter.

Major Components

The Kryptos robot featured several key components designed to optimize performance during the competition:

- Hybrid Chassis: A combination of an H-Chassis design in the back and a Bevel Gear setup in the front, providing a balance between maneuverability and structural support for various mechanisms.

- Drive Train: A four-wheel mecanum drive system allowing for precise strafing and movement across the field.

- Intake System: A surgical tube and compliant wheel-based intake mechanism designed for robust and efficient game element collection.

- Shooter Mechanism: A one-flywheel shooter optimized for speed and accuracy, using compression to stabilize the game elements before launch.

- Conveyor and Storage: A ramp and storage system designed to hold and feed game elements into the shooter, allowing for rapid scoring.

- Wobble Goal Arm: A custom 3D-printed claw mechanism, powered by servos, for precise lifting and depositing of game elements.

Prototyping and Iterations

Throughout the design process, the team engaged in extensive prototyping and testing to refine each subsystem. For example, the intake system went through multiple iterations to balance strength and flexibility, ultimately settling on a design that provided reliable intake performance without excessive material usage. Similarly, the shooter mechanism was tested with different compression levels to maximize accuracy and consistency.

The project also faced several challenges, such as optimizing the chassis design for both space and functionality and integrating multiple subsystems within a compact frame. To address these challenges, we employed a hybrid chassis design that allowed ample space for the robot's internal components while maintaining maneuverability. Additionally, we leveraged 3D printing and custom part fabrication to develop solutions for specific mechanical challenges, such as the wobble goal arm and shooter mounting.

Final Result

This Design Notebook summarizes the design of each major component in the robot. Primarily written and formatted by me, with assistance from other builders on the team.