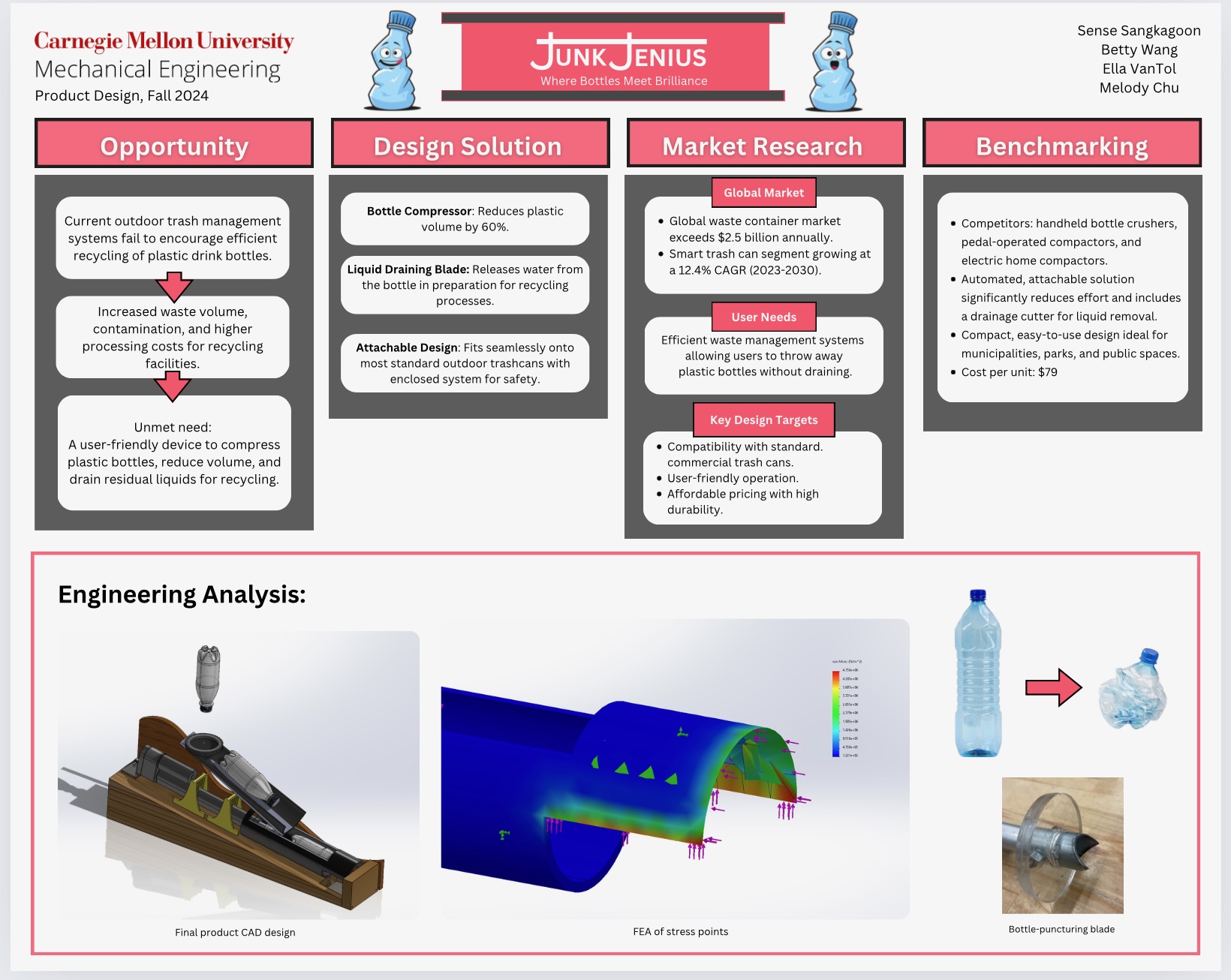

Junk Jenius

October - December 2024

The Junk Jenius: Plastic Bottle Recycling Machine is designed to make recycling easy,

accessible, and fun on our college campus. By automating the cutting, draining, and

crushing of plastic bottles in a single streamlined process, it is able to reduce common

barriers to recycling, like leftover liquids and the hassle of manual preparation.

» My contributions: CAD design and planning, prototype build, final design

mockup.

☆ Awarded Best Prototype at the Carnegie Mellon Engineering Expo.

Results Preview:

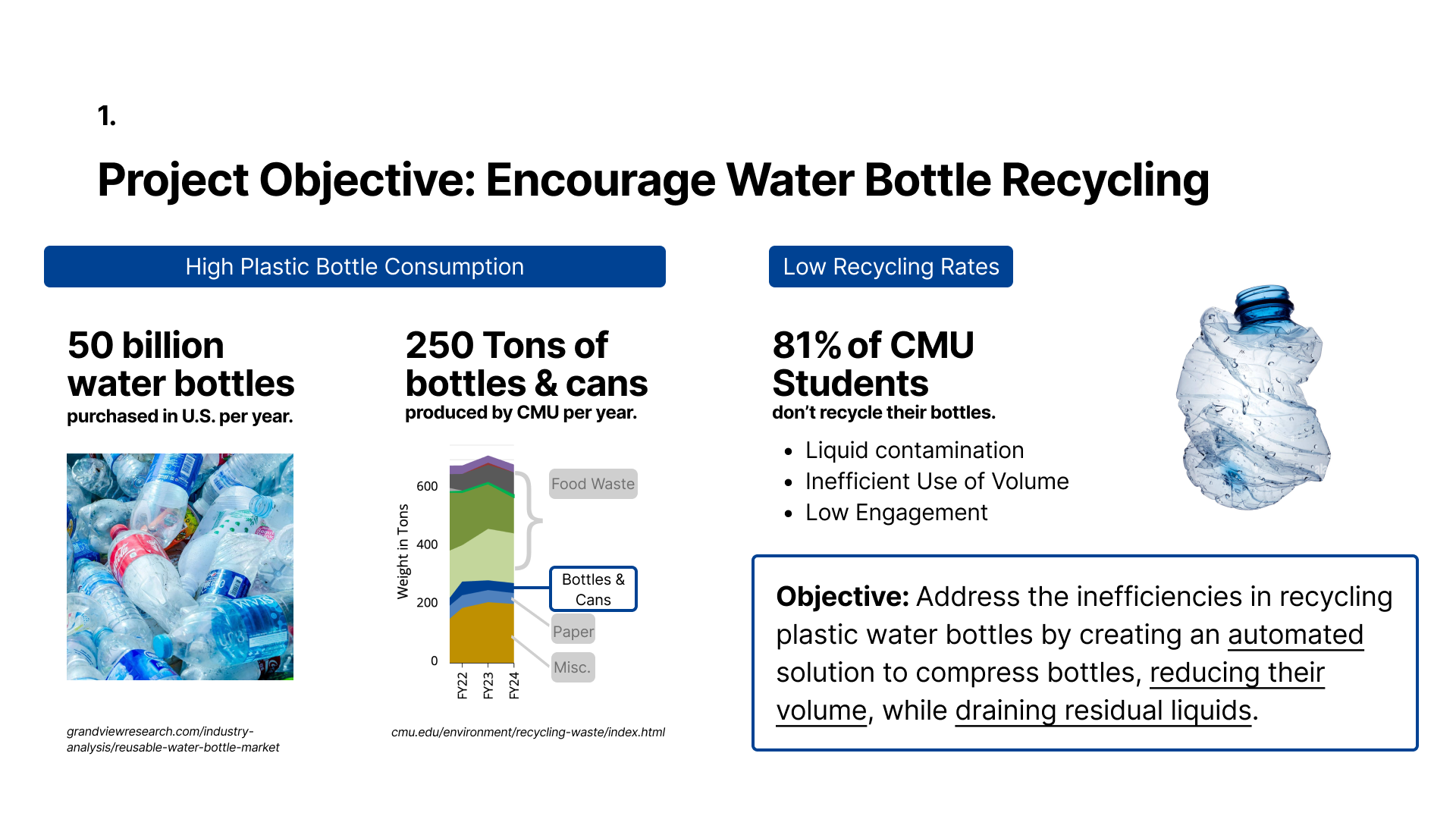

Project Goals

Objective: Address the inefficiencies in recycling plastic water bottles by creating an automated solution that compresses bottles in an engaging way, reducing their volume, draining residual liquids, and motivating people to recycle.

- 1. Simplify disposal process for the user

- 2. Reduce waste volume, optimizing transportation and disposal

- 3. Motivate users to recycle by improving engagement

Research: identify and understand the problem space.

Using Research to Validate the Problem

Our secondary research confirmed that plastic bottle use remains high, while recycling rates remain low, especially on CMU campus, where the meal plan always includes a plastic beverage bottle. My team confirmed this by observing a campus waste bin and counting the number of students who recycled their bottles. Through this, we found that over 81% of students do not recycle their bottles.

Finding Pain Points: User Process and Competitor Study

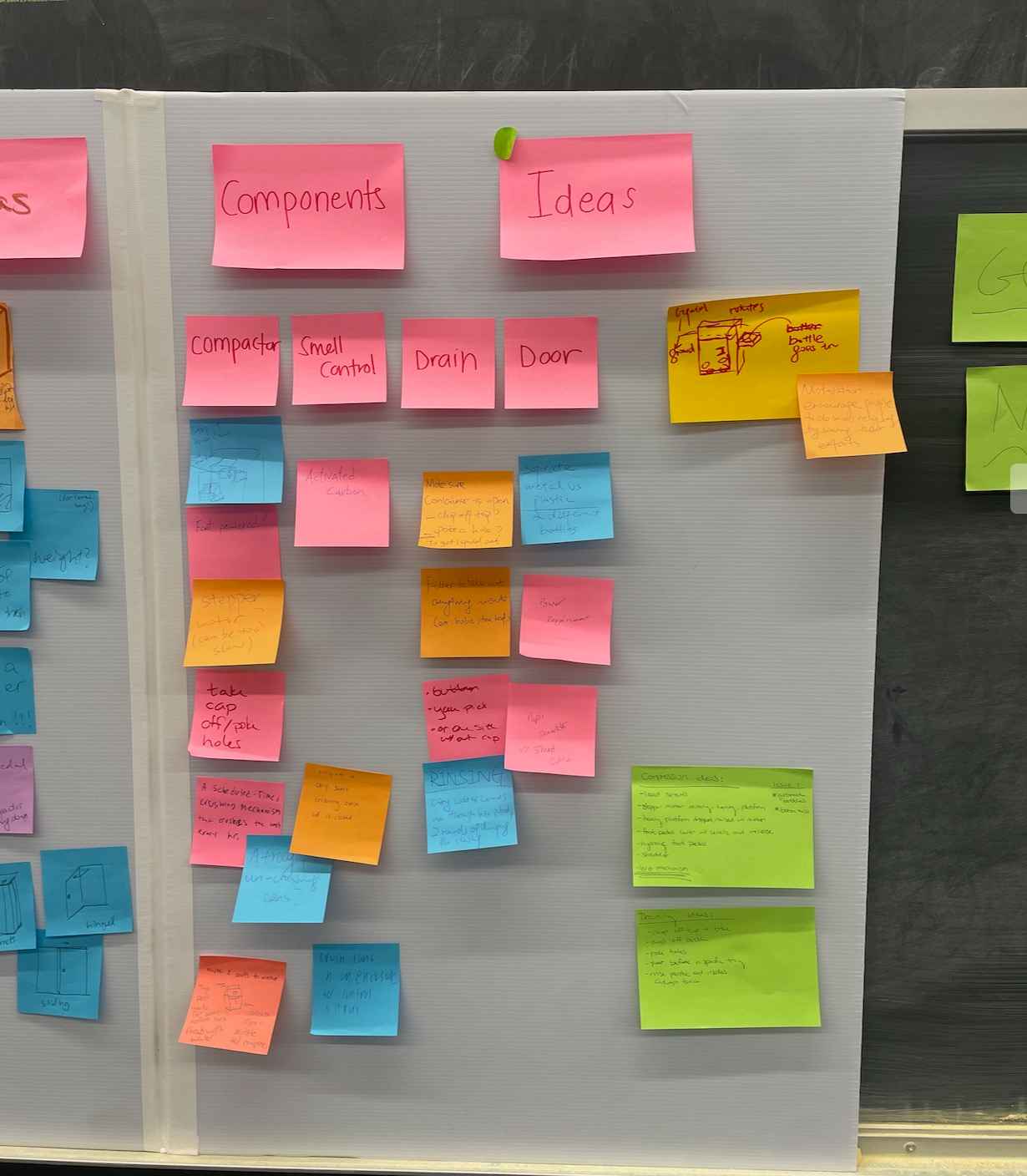

Next, we considered the user's perspective: what are the biggest barriers to recycling?

We conducted a competitor study on a manual trash compactor to learn how other companies

tackle the problem of waste disposal, especially when there is food/beverage waste involved.

I conducted user studies using a competitor trash compactor to find pain points. I placed the trash compactor in my house kitchen, which is shared by 4 college students (our target user). Although the trash compactor was not limited for only plastic bottles, it was helpful in determining pain points in waste disposal. Particularly, the competitor product was not intuitive to use, not structurally sound (parts broke off during normal use), and because it is manual, it is not that much more effective than compacting with your hands. However, the users

appreciated the novelty of the product (it's fun to crush stuff!) and the added hygiene (don't need to touch waste).

From this, we knew our solution should be automatic, easy to use, and durable enough to actually compact. Other key ideas: integrating a liquid drainage system, ensuring a one-button operation for ease of use, and incorporating the satisfaction of crushing stuff.

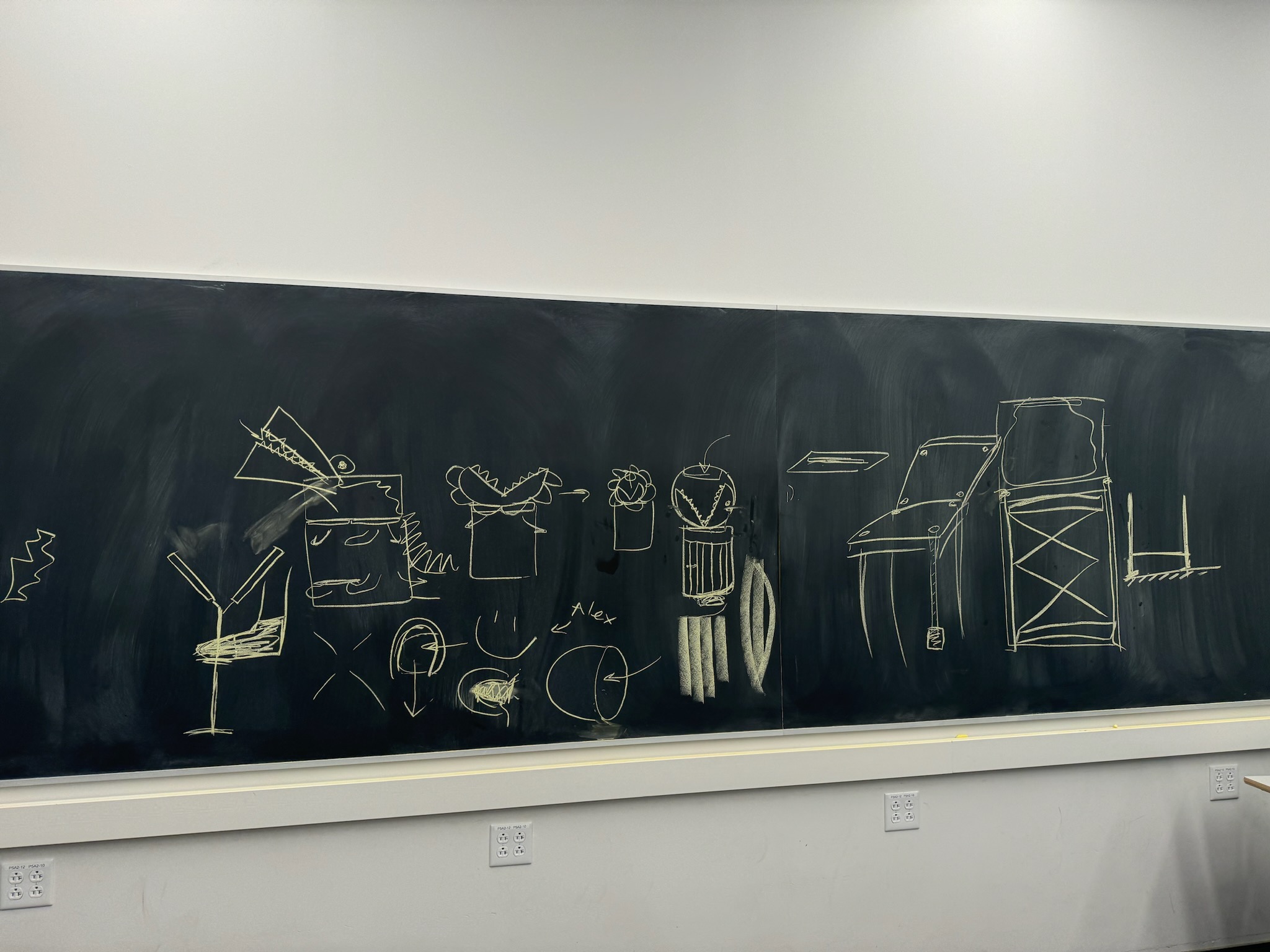

With our new criteria defined, we brainstormed features and what our solution could look like.

Main Mechanism Prototyping

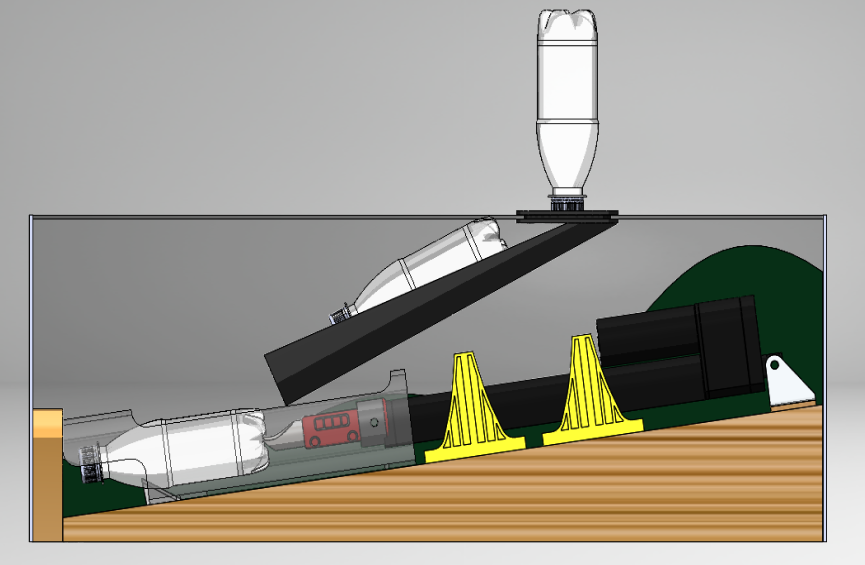

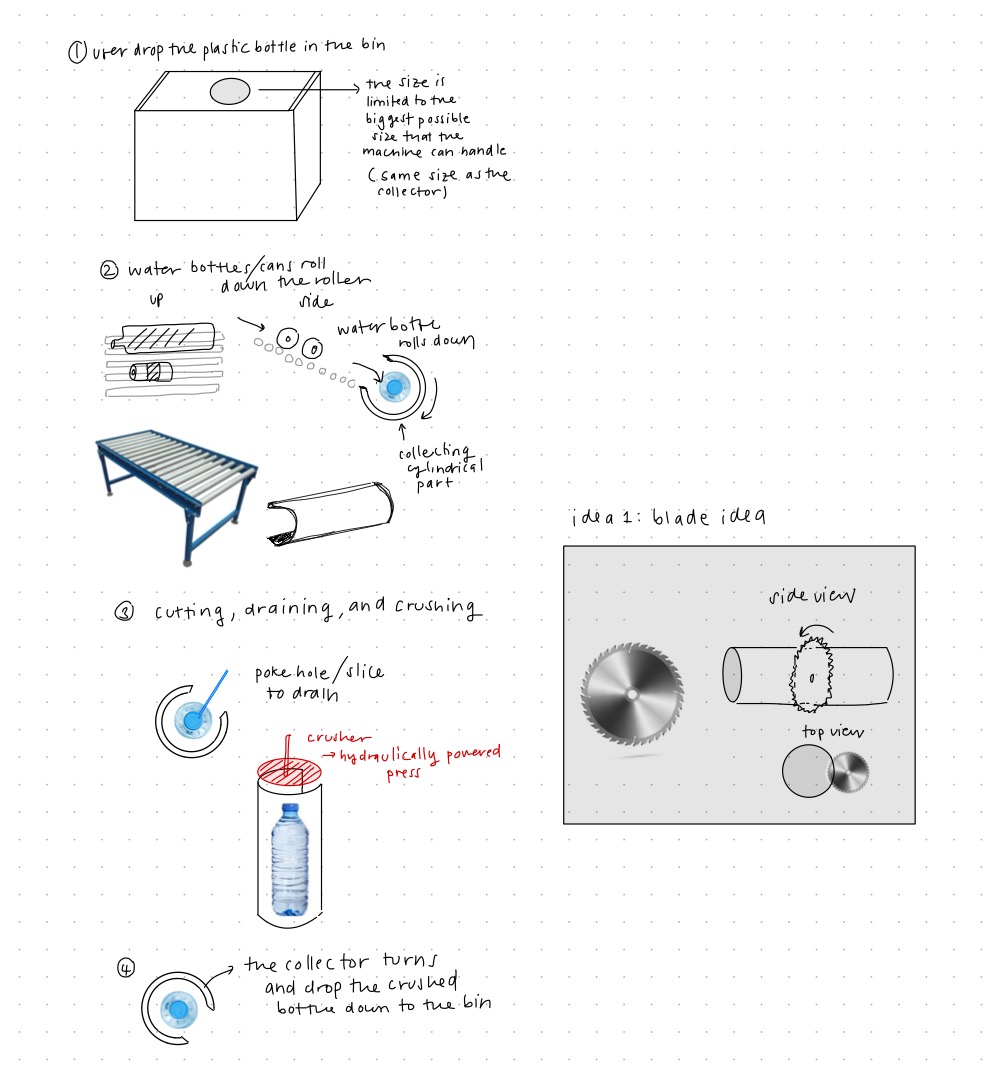

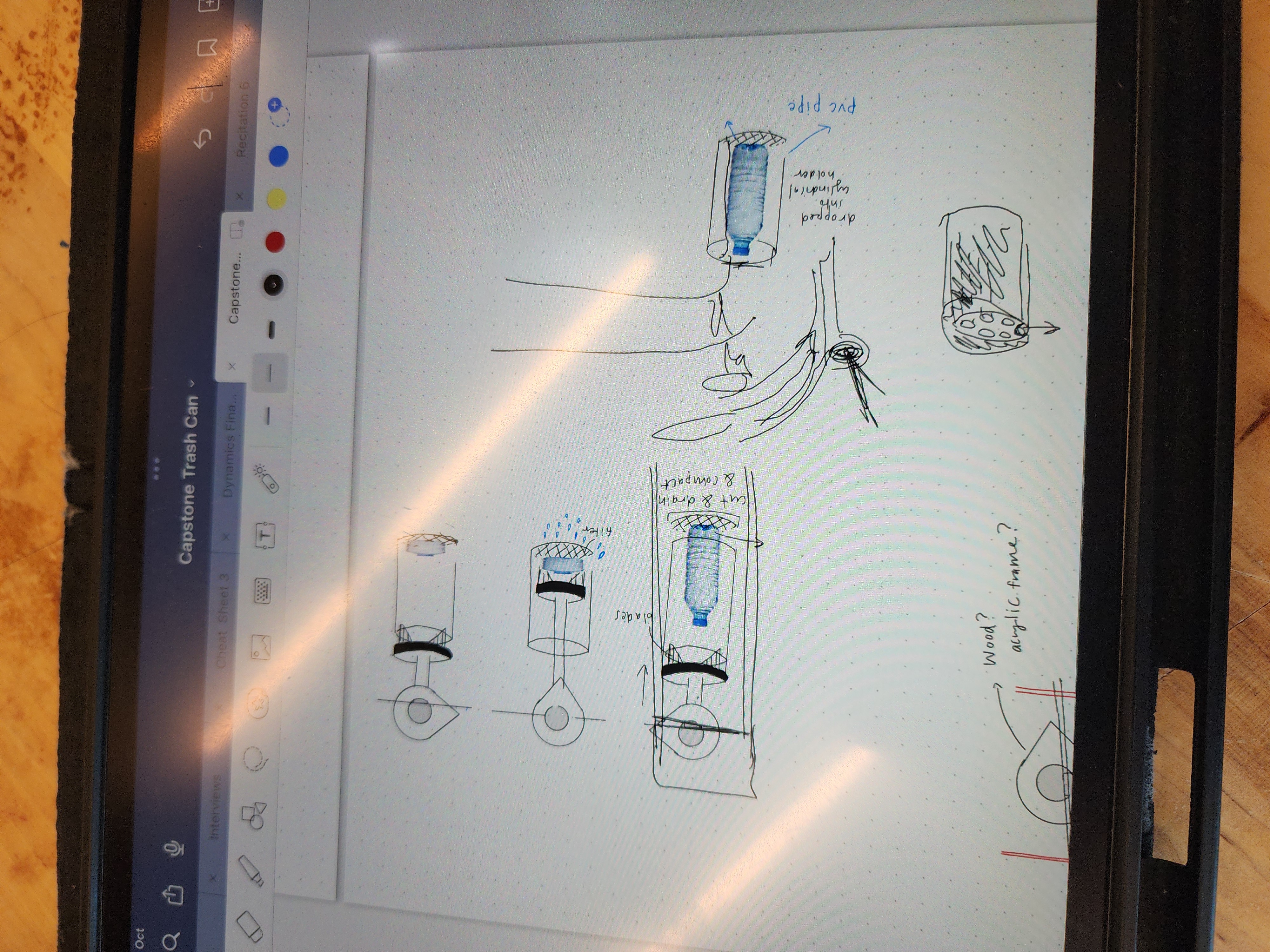

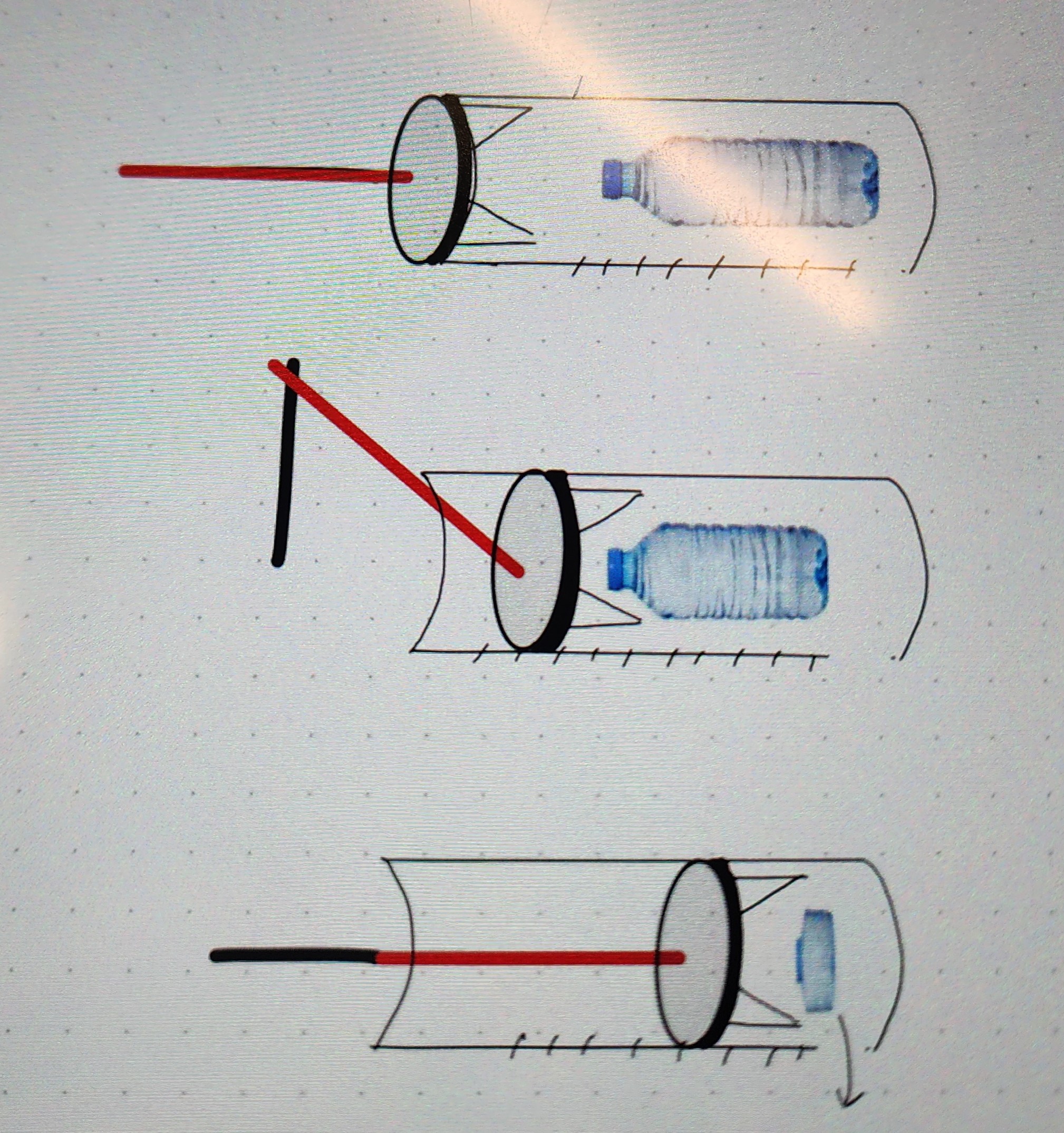

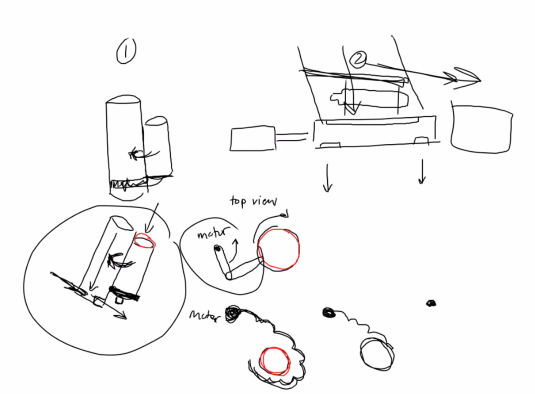

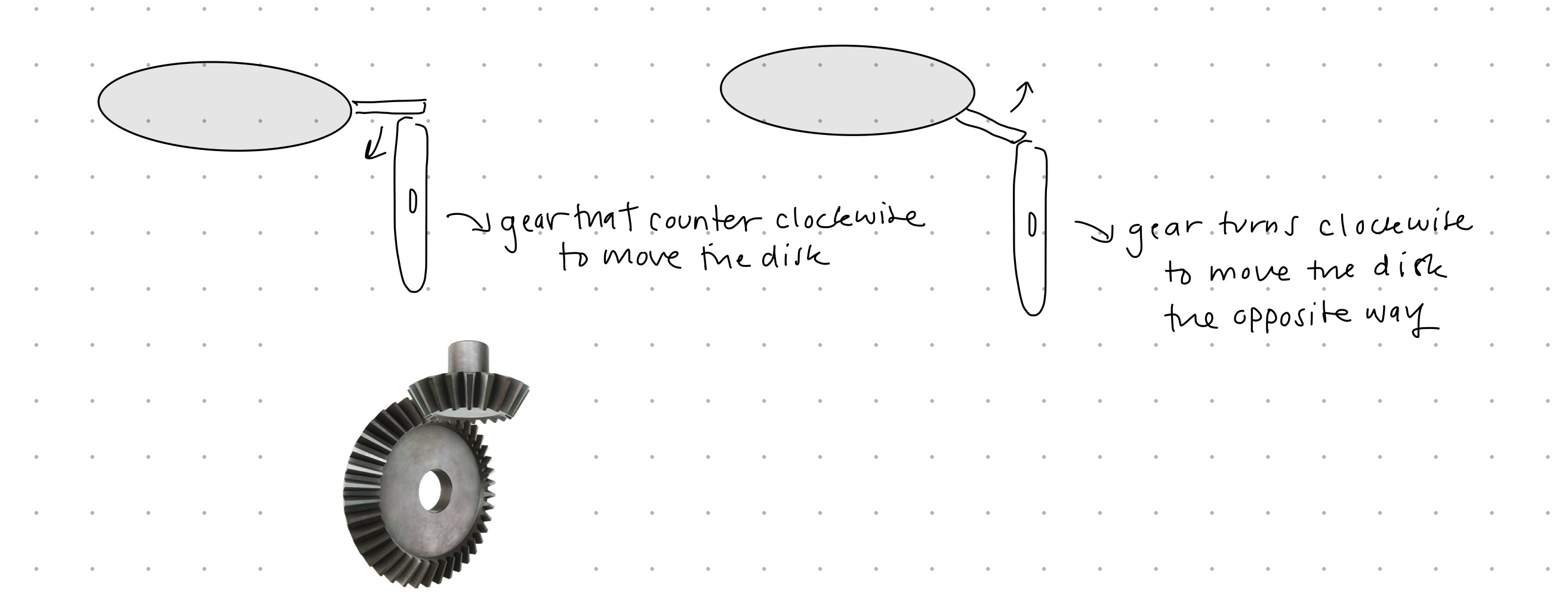

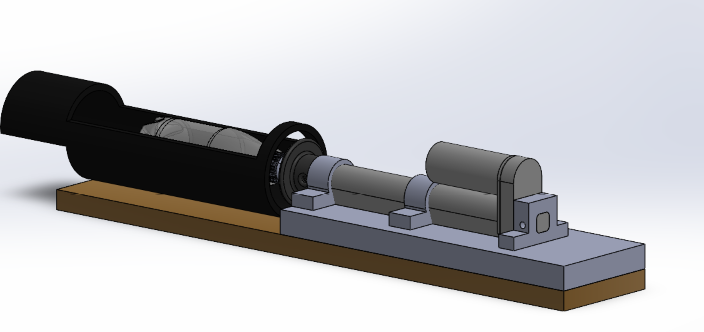

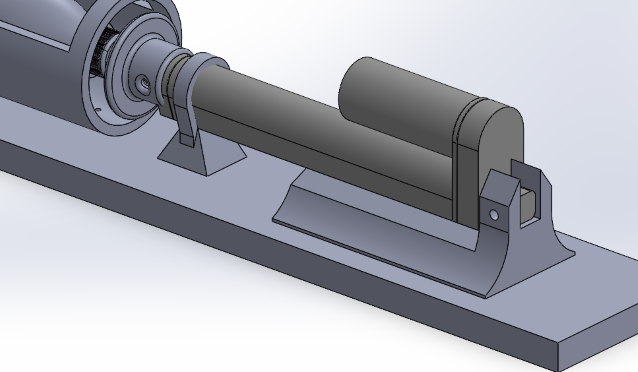

Next, we tackled our most critical design component: the crushing mechanism. Our initial approach used a linkage system, converting a motor or hand crank's rotational motion into the linear bottle-crushing motion. However, after I sketched and modeled it out, I noticed it took up a lot of space.

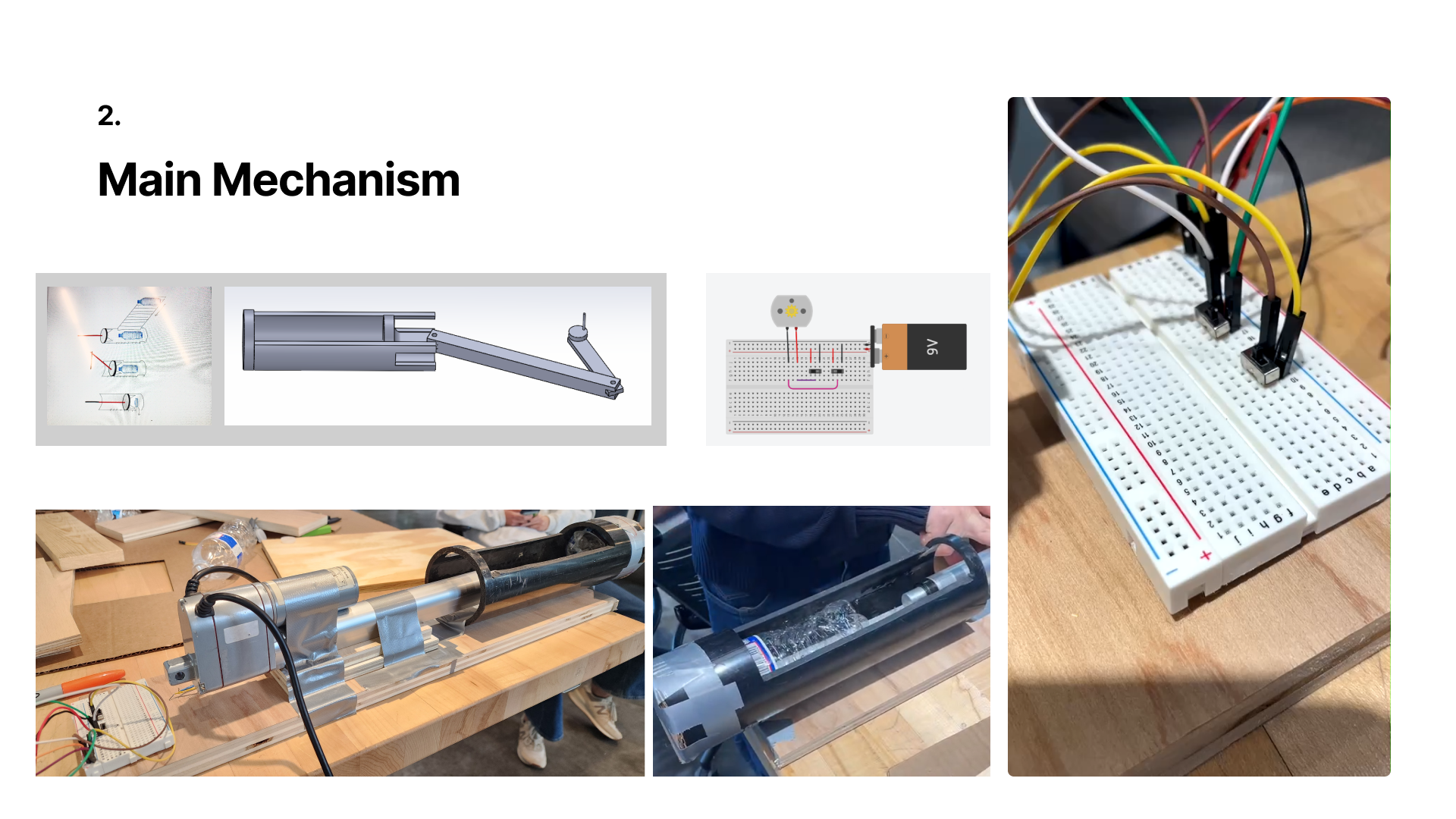

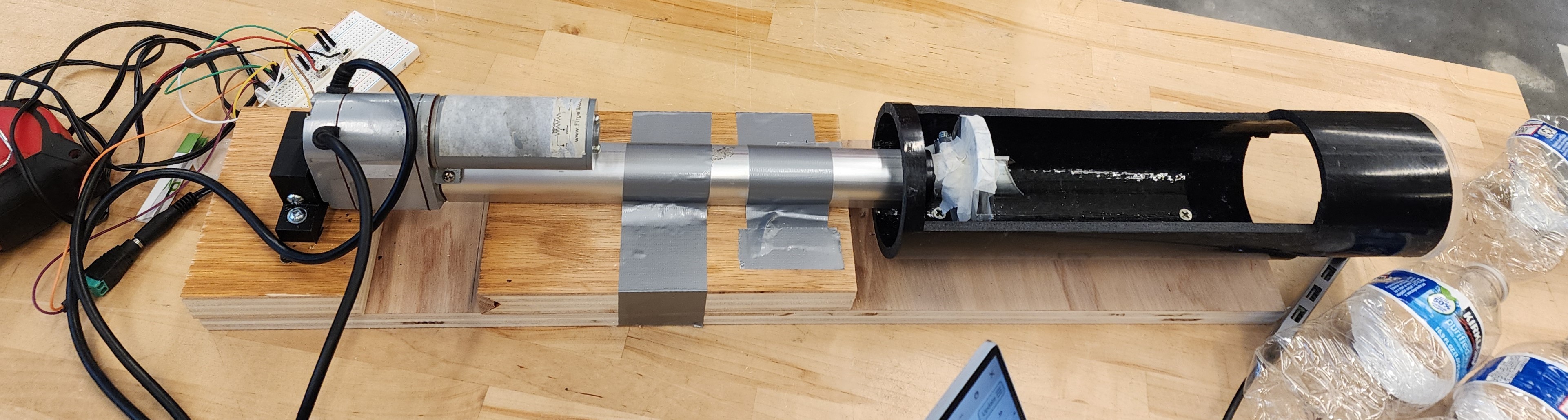

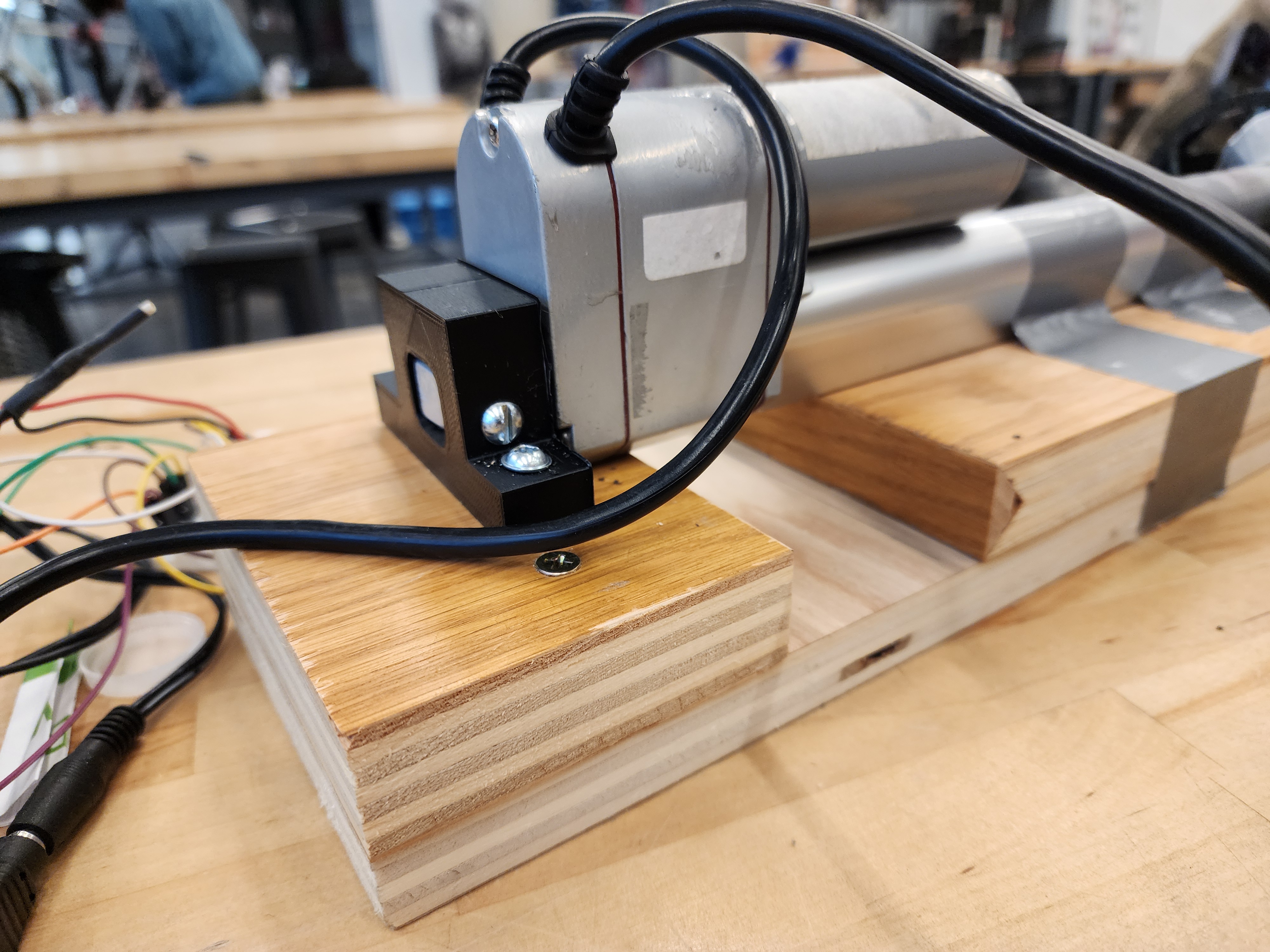

So, we switched to an off-the-shelf linear actuator borrowed from the school. This was much more compact, with an appropriate range of motion for crushing a single bottle. It would also allow the user to easily control its motion via a 3-way switch by reversing the direction of the current. I hooked up the actuator to a makeshift breadboard 3-way switch and tested it with water bottles, an old PVC pipe, and very rudimentary mounting.

Lo-Fi Prototyping

I built the rest of the prototype by manually machining scrap material in the woodshop/machine shop.

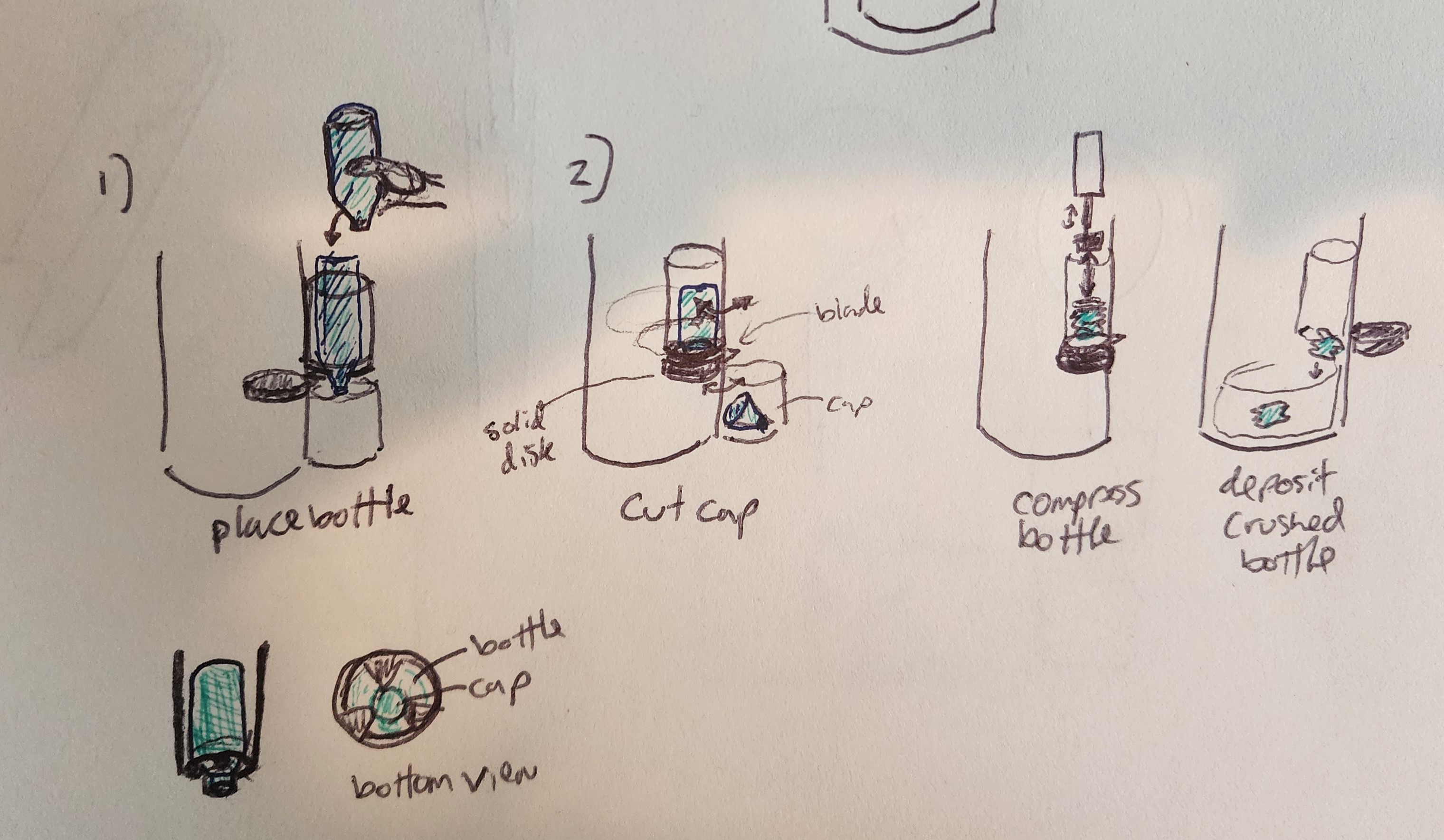

Bottle Processing Procedure: Next, my team debated: how are we incorporating the

crushing

mechanism? How are we mounting it?

I was a proponent for mounting it vertically; it would save

countertop/floor space, gravity would help with crushing and drainage, and there would also be an

added

level of safety from the separation between the user and the internal crushing components. To

demonstrate and communicate my idea to the rest of my team, I created some rough sketches, quick

CAD,

and created a lo-fi prototype.

However, lo-fi prototyping also demonstrated an issue: we would need additional components to control the individual rotation of the platforms, and the platforms rotating in and out would still take up space as well.

So, we went with a horizontal mount, but made sure to include a slanted ramp to aid drainage, and a safety separation between the user's hand and the crushing component.

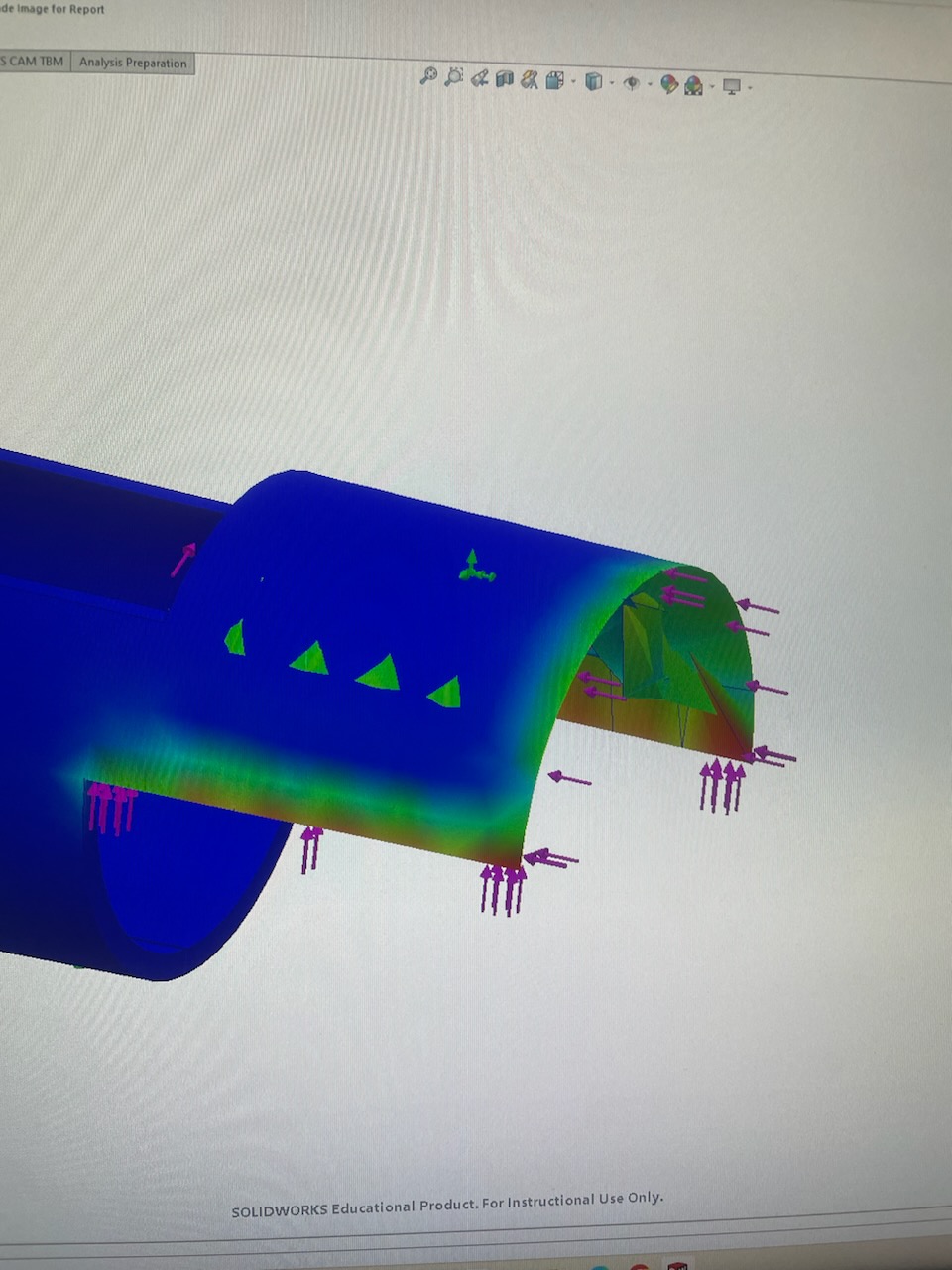

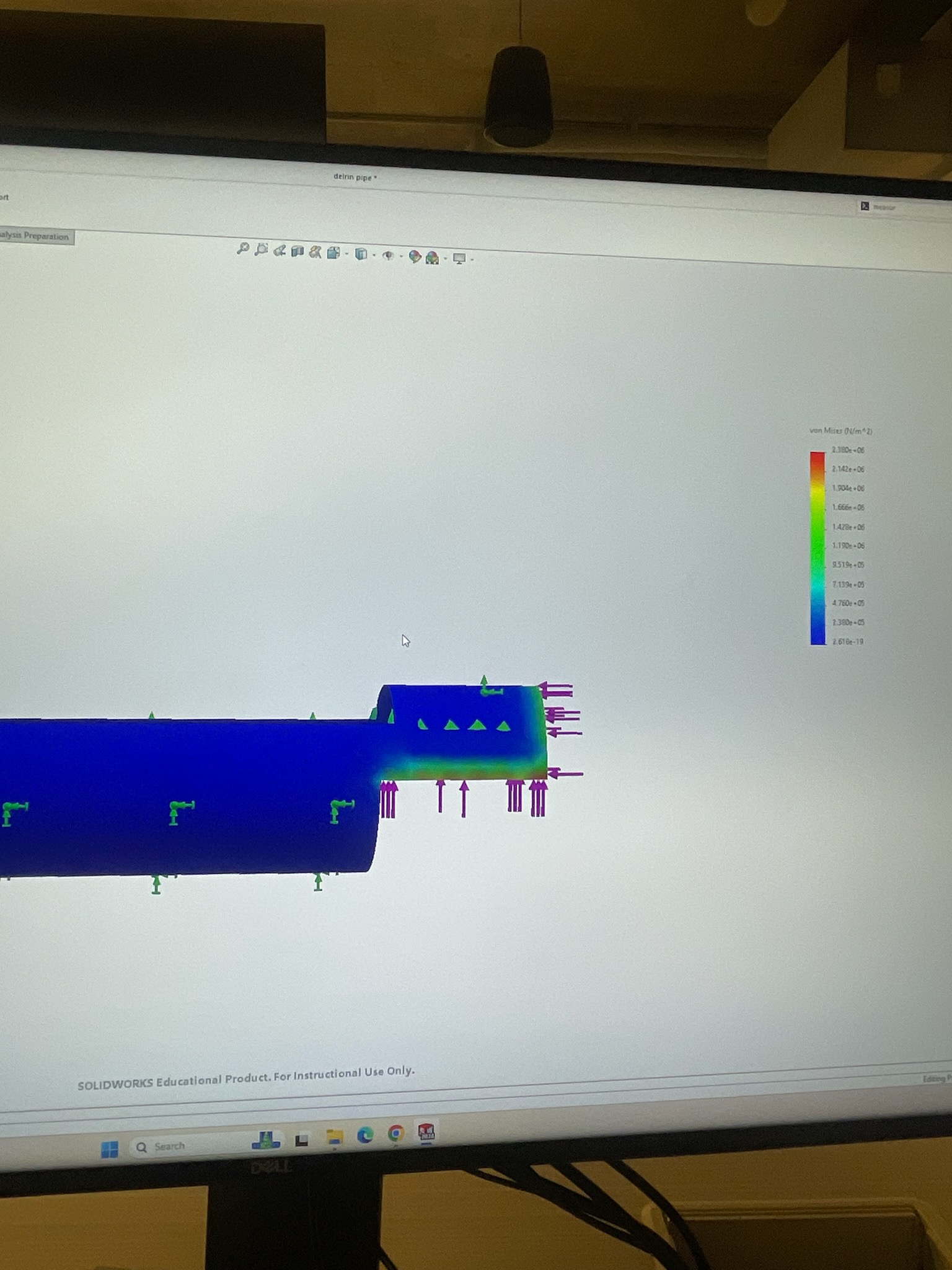

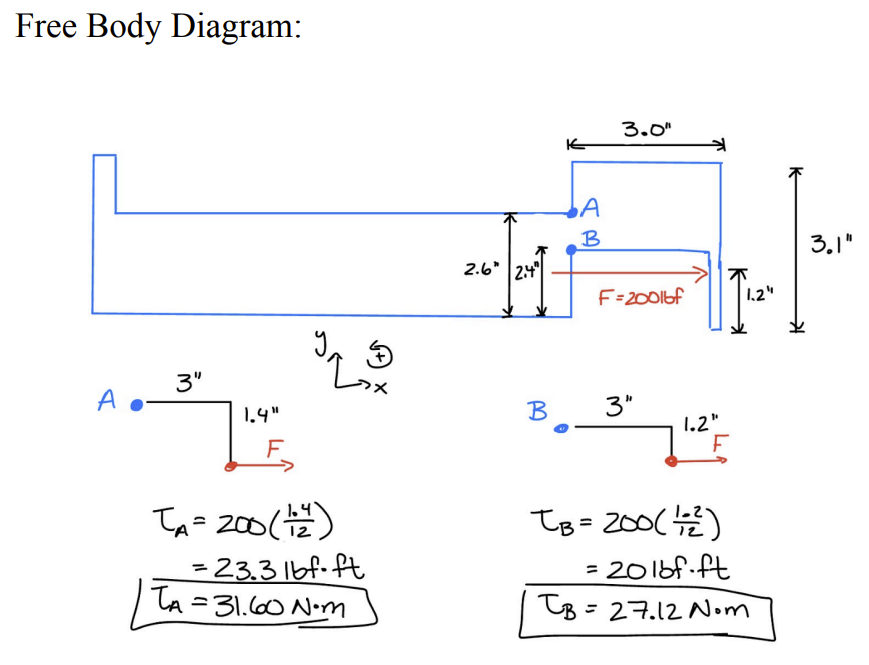

Stress Analysis

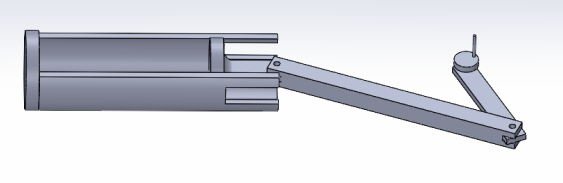

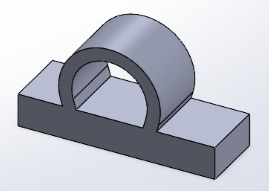

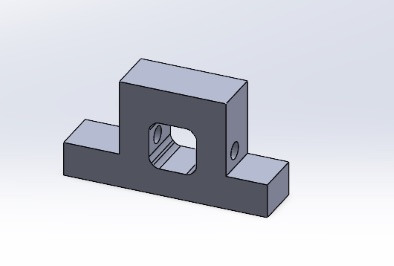

Another issue we tackled was prototype durability. The linear actuator we were using

was

rated for 200lbf, and we found it took ~50lbf to crush a water bottle (factor of safety = 4). The

next

weak point was the pipe with the cutouts, but we did hand

calcs and FEA to ensure it would hold. And finally, the linear actuator mount went through several

iterations, changing the shape to be thicker, have a wider footprint, and finally changing the

material

to counteract the torsional stress caused by the position and forces the mount would experience.

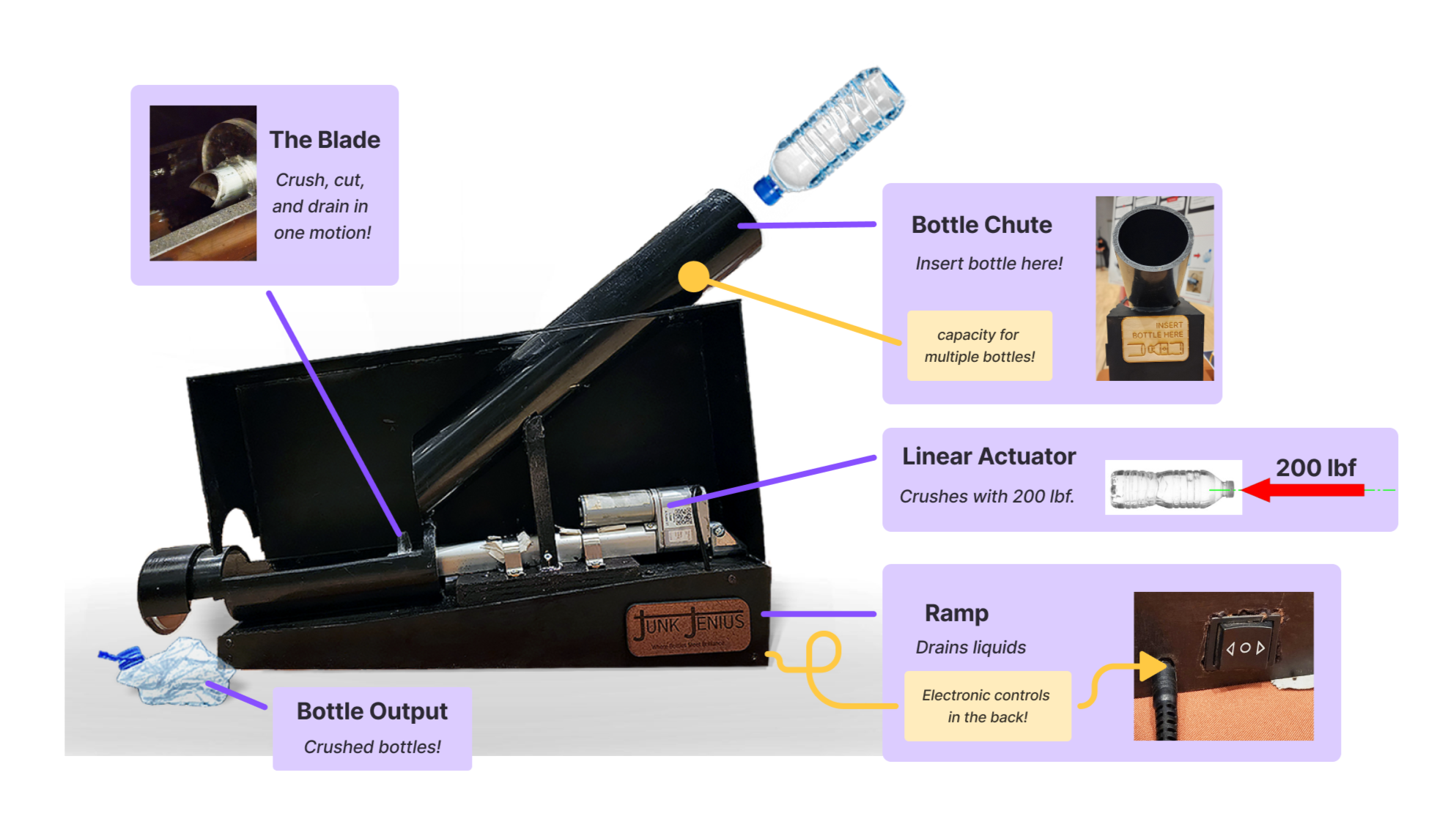

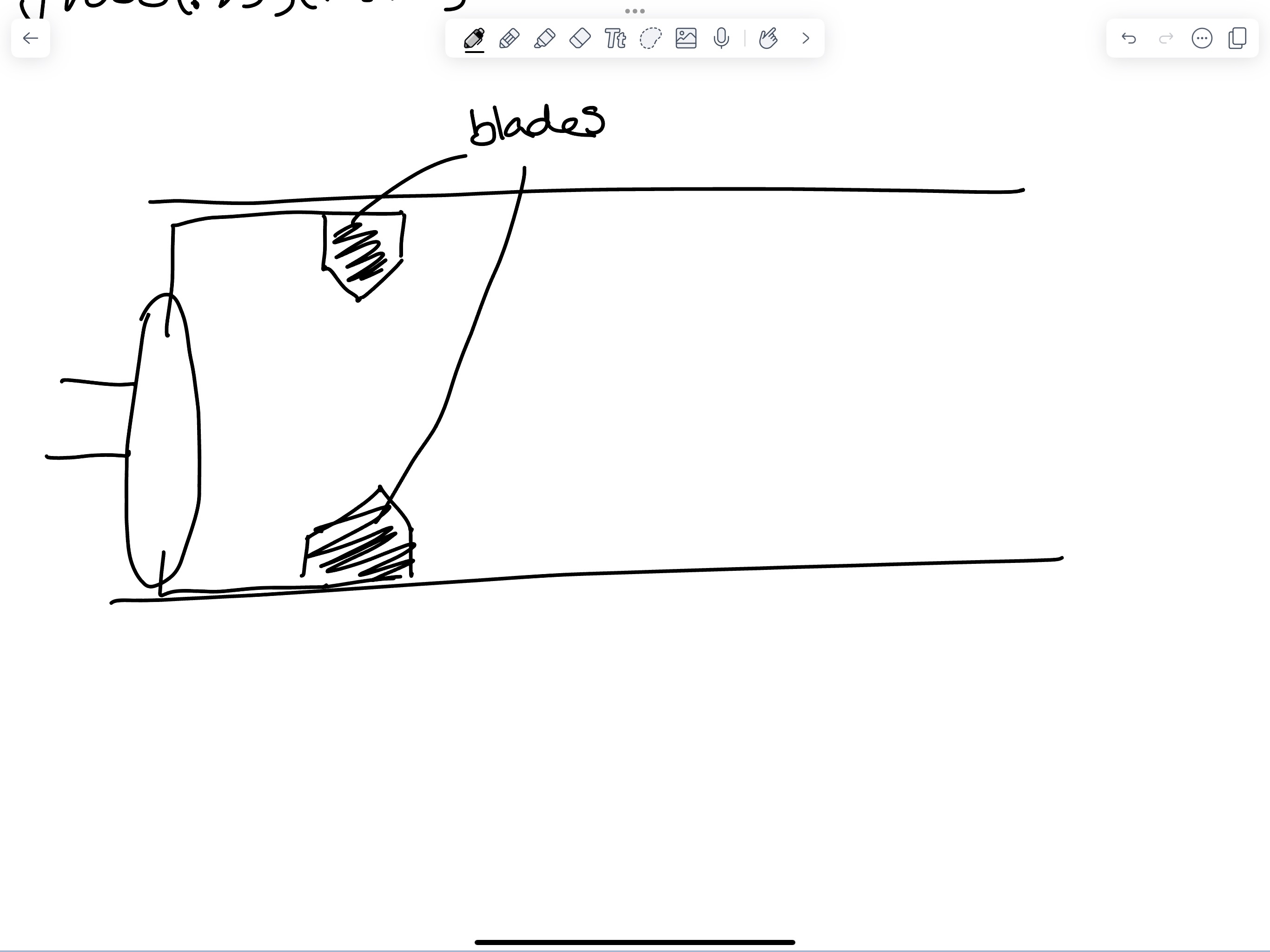

Finally, for the draining portion, my team went through several iterations of the blades. I optimized blade placement using CAD to ensure efficient, effective cutting while maintaining manufacturability with our available tools. We manually milled and sharpened a scrap metal pipe to create the blade. Through

testing, we modified it so that the curve of the points would allow the blade to pierce the bottle

without getting stuck on it when it retracts. I constructed the hollow ramp to help drained liquids

to flow out of the machine, which also houses the bulk of the electronic components for a cleaner look.

The

chute is long enough to hold multiple bottles, enabling rapid-fire crushing.

Safety measures: by default, the machine is "off" and only operates as long as the user holds

the

switch down. Also, the only user-facing components are the bottle insertion chute, the operation

switch,

and the hold that the crushed bottle drops out of. Everything else (moving components, blades,

crushing

chamber) is covered. So, we knew it was safe to allow anyone to use.

Final Result

The final design successfully integrates cutting, draining, and crushing into a single compact

machine.

It also successfully met our goals of being functional, durable, simple, and user-friendly.

Final Prototype Features:

As a final touch, I designed a final mockup for the Expo, incorporating Pittsburgh iconography to resonate with our local campus users. The blade holder is shaped like Pittsburgh's iconic red bus, holding the blades as a "snowplow" that will crash through and destroy the water bottles. As the mechanism operates, the bus zooms through Pittsburgh’s iconic bridges (aka the linear actuator mounts), while the outer frame mirrors the city's hilly skyline. The front wall is constructed from clear acrylic, allowing users to watch the satisfying destruction. We showcased this interactive prototype and mockup during the 2024 CMU Engineering Design Expo, receiving a lot of positive reactions! In addition to our group's pitch and explanation of the project, we gave live demos of the machine actually crushing a variety of bottles and allowed people to try it themselves too. By popular vote amongst attendees, our project was awarded "Best Prototype," validating its creativity, functionality, and broad appeal. It was well-received during user testing, with feedback highlighting its creativity and interactivity with users, and functional potential to enhance recycling rates in public spaces.

Reflection

As my final engineering capstone project, this was a very exciting experience. I felt that I was an integral and essential part of this team, and was proud of my contributions in CAD design, prototyping, and general teamwork. The most satisfying part was seeing our concept evolve into a functional prototype that not only addressed a real-world problem we saw around us, but brought an element of joy to its users. I think it resonated with our audience because it was relevant to them and it was fun. Because our school is in Pittsburgh, everyone could relate to the iconic local elements. The Pittsburgh-inspired aesthetic design and interactive functionality helped make the machine not just practical but also enjoyable to use. If we had more time, I would probably want to focus on further developing the prototype's visuals to match the mockups, include more interactive elements like displaying how many bottles it has recycled, and streamlining the manufacturing process to reduce material waste. But all in all, given our time and resource constraints, I am extremely happy with the final product!